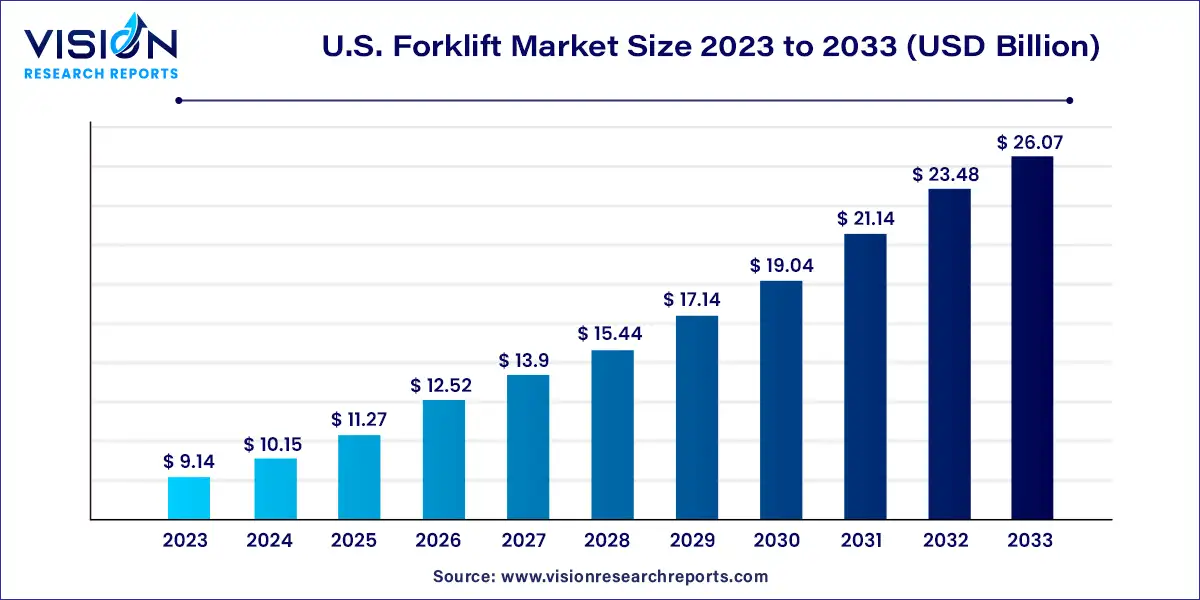

The U.S. forklift market size was estimated at around USD 9.14 billion in 2023 and it is projected to hit around USD 26.07 billion by 2033, growing at a CAGR of 11.05% from 2024 to 2033.

The U.S. forklift market is a vital component of the nation's industrial and logistics sector, playing a pivotal role in the movement and transportation of goods across various industries. With the increasing demand for efficient material handling solutions, the forklift market in the United States has witnessed significant growth and evolution in recent years.

The growth of the U.S. forklift market is propelled by various factors contributing to its expansion and evolution. One of the primary drivers is the increasing demand for efficient material handling solutions across industries such as manufacturing, logistics, construction, and warehousing. This demand is fueled by the rising trend of e-commerce and the need for streamlined supply chain operations. Additionally, advancements in technology, particularly in areas such as automation, electrification, and connectivity, are reshaping the market landscape. The shift towards electric forklifts, driven by their eco-friendliness and cost-effectiveness, is further driving market growth. Moreover, the integration of telematics, IoT, and AI capabilities is enhancing operational efficiency and enabling predictive maintenance, thereby optimizing fleet management. Overall, these growth factors underscore the promising trajectory of the U.S. forklift market as it continues to meet the evolving needs of industries and embrace innovative solutions.

The retail and e-commerce sector dominated the revenue share in 2023, holding 25%. Forklifts play a crucial role in material handling and warehousing within this sector. The surge in online shopping, driven by evolving consumer preferences, has significantly expanded in recent years. This growth is facilitated by increased social media usage and the appealing cost and convenience factors offered by brands. According to Tidio, as of 2023, the U.S. boasts over 268 million online shoppers, marking a 16.2% increase from 2020. Additionally, a staggering 70% of the U.S. population engages in online shopping. Consequently, there has been a notable expansion of warehousing facilities in the retail and e-commerce sector, resulting in heightened demand for forklifts.

The logistics sector is projected to witness an 11.72% growth rate by 2033. Efficient material handling solutions are indispensable for logistics companies in the U.S. to maintain seamless supply chain operations. Given the diverse sizes and weights of containers they handle, forklifts equipped with container handlers or reach stackers are instrumental. These forklifts efficiently move and stack containers in ports and logistics hubs, optimizing cargo handling and storage space. They play a vital role in cross-docking facilities, facilitating direct transfer of goods from inbound to outbound trucks with minimal storage time. The trillion-dollar logistics industry in the U.S. underscores the substantial demand for material handling equipment within this sector.

In 2023, the Class 3 segment secured a significant market share of 44%. This segment primarily encompasses electric motorized hand trucks, with pallet jacks and tow tractors (tuggers) being the most prevalent types. Additionally, pallet stackers fall under Class 3 equipment and are particularly valuable for swiftly unloading and transferring carts or pallets both horizontally and vertically within warehouse environments. These stackers are characterized by their compact design and boast a load capacity ranging from 4500 lbs to 10000 lbs, making them an optimal choice for maneuvering in smaller spaces. They are widely employed for moving items requiring low elevation, facilitating convenient transportation of goods across warehouse floors without necessitating placement on high racks or shelves.

Forecasts indicate that the Class 1 segment will witness a notable compound annual growth rate (CAGR) of 11.85% through 2033. Class 1 forklifts find extensive applications across major industrial sectors like food & beverage, retail, and warehousing, offering advantages such as minimal noise, low maintenance requirements, and zero emissions. Notably, 3-wheel electric forklifts within this segment are advantageous for indoor production settings with smooth flooring and limited space, where maneuverability is crucial. These forklifts typically support load capacities ranging from 1,500 lbs to 4,000 lbs. Conversely, 4-wheel electric forklifts are better suited for rugged outdoor terrains and applications. They boast higher load capacities ranging from 3,000 lbs to 12,000 lbs, catering to heavier lifting requirements.

In 2023, electric forklifts commanded a significant revenue share of 74% in the market, establishing their dominance in terms of power source. These forklifts, powered by electricity, offer numerous advantages compared to their Internal Combustion Engine (ICE)-powered counterparts. Benefits include zero emissions, reduced noise levels, minimal maintenance requirements, and lower running costs. With a growing emphasis on environmental concerns and the depletion of fossil fuel resources in the United States, there's a heightened demand for sustainable, efficient, and long-lasting solutions. According to the American Journal of Transportation, an estimated 250,000 out of 330,000 forklifts projected to be sold in the country by 2029 will be battery-electric, reflecting businesses' preference for environmentally friendly solutions in forklift operations.

The popularity of electric forklifts is further bolstered by various regulations implemented in the country in recent years. California stands out as a leader, having regulations mandating forklift electrification. Additionally, the California Air Resources Board (CARB) is developing legislation aimed at phasing out the sale of Large Spark-Ignition (LSI) forklifts starting in 2026. Another initiative, the Clean Off-Road Equipment (CORE) Voucher Incentive Project in California, encourages companies to purchase or lease zero-emission off-road equipment. These regulatory measures and incentive programs are key drivers of the escalating demand for electric forklifts across the United States.

In 2023, the 5-15 ton load capacity segment held a significant revenue share of 61%. The surge in residential and commercial projects across the U.S. has propelled the demand for forklifts within this capacity range. These forklifts are adept at handling materials like steel, pallets, and bricks, crucial components in building construction. Renowned for their efficiency in mechanized loading and transportation over short distances, they play a vital role in construction activities. The selection of forklifts within this capacity range is often dictated by the nature of the materials to be handled. Furthermore, advancements in materials and technologies related to forklift construction have contributed significantly to enhancing load capacities.

Conversely, the below 5 ton segment is anticipated to exhibit the highest growth rate of 11.64% through 2033 in the U.S. market. These compact and versatile forklifts enable organizations to efficiently manage various load sizes. Innovations in materials, power systems, and ergonomics are key drivers behind the development of more efficient and robust forklifts capable of lifting heavier loads while maintaining maneuverability. Additionally, factors such as safety regulations enforced by OSHA, evolving industry demands, and environmental considerations have played pivotal roles in shaping the growth trajectory of this segment

In 2023, lead-acid batteries claimed the largest revenue share of 63% in the market. Renowned for their reliability and ability to provide high-power surges, these batteries are extensively utilized in electric forklifts. Their high energy density facilitates the storage of large quantities of energy in smaller spaces, making them a preferred choice. Furthermore, lead-acid batteries boast comparatively lower upfront costs than lithium-ion batteries, and their durability is underscored by their resilience to vibrations, shocks, and extreme temperatures.

Conversely, the lithium-ion segment is poised to exhibit the highest compound annual growth rate (CAGR) of 13.53% through 2033. Increasing environmental awareness has prompted eco-conscious consumers to opt for lithium-ion battery forklifts, thereby driving market expansion. Lead-acid batteries typically contain toxic chemicals like sulfuric acid and lead, posing environmental risks if improperly disposed of. In contrast, lithium-ion batteries offer a cleaner alternative, being maintenance-free, possessing a longer lifespan, and exhibiting greater efficiency. Additionally, the chemistry of lithium-ion batteries enables faster charging and extended operating times per charge, further enhancing their appeal and driving overall demand.

By Class

By Power Source

By Load Capacity

By Electric Battery Type

By End-use

Cross-segment Market Size and Analysis for

Mentioned Segments

Cross-segment Market Size and Analysis for

Mentioned Segments

Additional Company Profiles (Upto 5 With No Cost)

Additional Company Profiles (Upto 5 With No Cost)

Additional Countries (Apart From Mentioned Countries)

Additional Countries (Apart From Mentioned Countries)

Country/Region-specific Report

Country/Region-specific Report

Go To Market Strategy

Go To Market Strategy

Region Specific Market Dynamics

Region Specific Market Dynamics Region Level Market Share

Region Level Market Share Import Export Analysis

Import Export Analysis Production Analysis

Production Analysis Others

Others